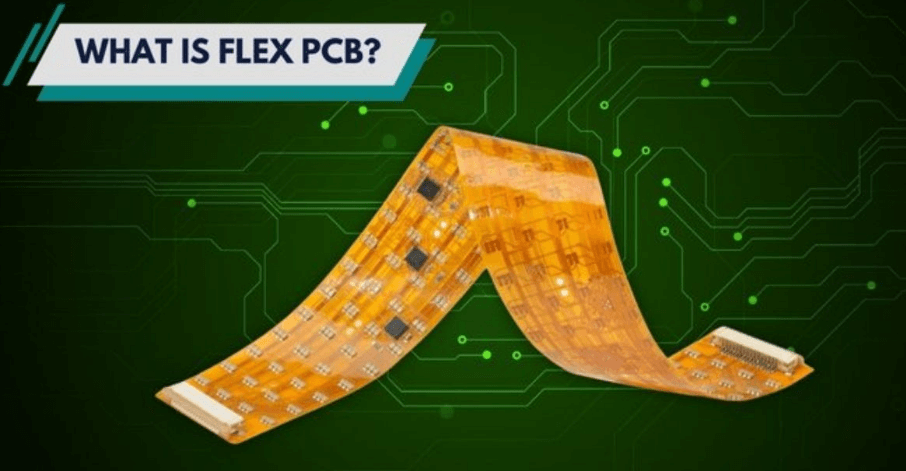

What Is Flex PCB?

A flex PCB is a flexible printed circuit board. It can bend and twist. Flexible circuits are used in small and smart devices. They save space and reduce weight. Electronics designers like them for wearables and smartphones. Flex pcb connects parts in a compact way. They are different from rigid pcb.

Flexible electronics boards improve device performance. They are reliable and strong. High-density flex circuits allow more connections in less space. Today, flex PCB technology is popular in modern electronics.

Flex PCB Benefits

Flex PCB or flexible circuit boards that band easily. They give space and reduce weight flux pcb improve electronic devices performance. They are used in smartphones, wearables and medical devices. These pcb offer durable and long lasting reliability. Flex pcb allows complex circuit designs in small areas.

They also reduce assembly time and production cost. Using a high quality flex pcb shows better signal and integrated and efficient electronics. Flex pcb are trusted solutions for modern electronic manufacturing.

See also: How Businesses Benefit from WhatsApp Web Version Login and Telegram Chinese

Flex Vs Rigid PCB

Flex is bend-able and lightweight .RigidPCB are stiff and strong. Flex PCB saves space and fits in small devices. Rigid pcb are easy to manufacture and cost less. pcb are used in smartphones and medical devices. Rigid pcb are used in computers.

The servers and industrial electronics choosing. The right PCB depends on design needs, device size and performance requirements. Understanding the flex vs rigid pcb helps improve electronics efficiency and product reliability.

Flex PCB Manufacturing Process

The flux PCB manufacturing process starts with designing the circuit. Thin copper layers are added to the flexible substrate. Next the itching process creates the circuit pattern. Laminating protects the layers drilling and plating makes connections between layers. After that solder mask and skills green printing are applied.

Finally the flex PCB is tested for quality and reliability. This process shows durable lightweight and hyperformance flex pcb. Using up trusted PCB manufacturer grants is accurate and efficient production.

Flex PCB Applications Today

Flex pcb are used in many modern electronics. They appeared in smartphones with tablets and variable devices. They are also in medical equipment, drones and automotive electronics. Flex PCB as a way to help compact designs improve device performance and reliability.

Companies use flex PCB for the high speed circuit and complex electronics. Their lightweight and durable design makes them ideal for advanced technology products. Flex PCB trusted choice for two days electronics manufacturing.

Choosing Flex PCB Manufacturer

Choosing the right flux PCB manufacturer is very important. Look for experience in making high quality pcb checking. If they use our custom PCB design and rapid prototyping a good manufacturer provides durable and reliable. They should use advanced technology and quality materials.

Also about production capacity testing method and delivery time. At trusted PCB supplier insurance official electronics manufacturing choosing. The right partner helps improve device performance and reduce errors in electronic products.

Future Of Flex PCB

The future of flex and FastTurn PCB looks very bright. Flex pcb will be used in wearables, smart devices, and medical electronics. They allow compact designs and save space. New materials and advanced manufacturing will make them more durable and efficient.

Flex pcb will support high speed circuits and complex electronics. Companies are focusing on custom flax PCB solutions and rapid prototyping service. The future promises light weight and high performance electronics using the flex pcb.

Conclusion

Flex pcb are flexible circuit boards that bend and fit in small devices. They are different from rigid pcb and save space Flex pcb are used in smartphones, wearables, and medical electronics They offer durability, lightweight design, and high performance.

Choosing a trusted PCB manufacturer ensures quality flex pcb, Flex pcb improve device reliability and electronics efficiency They are a modern solution for compact and advanced electronic designs, making them essential in today’s technology

FAQ’s

Are Flex PCBs durable?

Yes, Flex PCBs are strong and reliable. They can handle bending and vibration better than rigid PCBs.

Do Flex PCBs reduce device weight?

Yes, Flex PCBs reduce weight. They remove the need for bulky connectors and cables.

Is Flex PCB manufacturing expensive?

Flex PCB cost depends on design and layers. It may cost more than rigid PCB but saves assembly cost

Can Flex PCBs support high-speed signals?

Yes, high-density Flex PCBs support high-speed circuits. They offer better signal performance